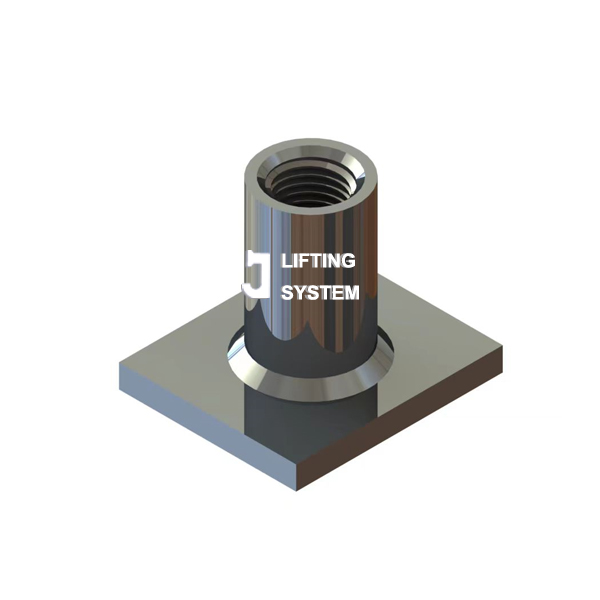

Heavy Duty Foot Anchor Socket

Introducing Chontan's Heavy Duty Foot Anchor Socket, an essential component for securing structures in demanding environments. As a leading manufacturer and supplier, Chontan's factory is dedicated to producing high-quality anchor sockets designed to withstand heavy loads and harsh conditions.

Send Inquiry

Product Description

Introducing Chontan's Heavy Duty Foot Anchor Socket, an essential component for securing structures in demanding environments. As a leading manufacturer and supplier, Chontan's factory is dedicated to producing high-quality anchor sockets designed to withstand heavy loads and harsh conditions.

The Heavy Duty Foot Anchor Socket is engineered with precision and durability in mind, making it ideal for a wide range of applications, including bridges, highways, and industrial facilities. Its robust construction ensures reliable performance, even in the most challenging environments.

Manufactured with advanced techniques and quality materials, Chontan's Heavy Duty Foot Anchor Socket undergoes rigorous testing to ensure compliance with industry standards and specifications. Our commitment to quality and excellence is reflected in every aspect of the manufacturing process.

Engineered for strength and reliability, the Heavy Duty Foot Anchor Socket provides secure anchoring for structures, offering peace of mind to engineers, contractors, and project managers. Its versatile design allows for easy installation and compatibility with various types of anchoring systems.

Chontan's Heavy Duty Foot Anchor Socket is the preferred choice for projects where safety, reliability, and durability are paramount. With our unwavering dedication to quality and customer satisfaction, Chontan is your trusted partner for all your anchoring needs.

Choose Chontan for premium-quality Heavy Duty Foot Anchor Sockets backed by decades of manufacturing expertise and a commitment to excellence. Partner with us and experience the reliability and performance you can trust in every anchor socket.

|

Size |

S.W.L |

Code |

Dimensions (mm) |

|||

|

Tons |

L |

D |

d |

e |

||

|

Rd12 |

1.3 |

130 |

16 |

10 |

22 |

|

|

Rd16 |

2.5 |

LHS05-16200 |

200 |

21 |

14 |

27 |

|

Rd20 |

4.0 |

LHS05-20258 |

258 |

27 |

18 |

35 |

|

Rd24 |

5.0 |

LHS05-24325 |

325 |

31 |

20 |

43 |

|

Rd30 |

7.5 |

LHS05-30400 |

400 |

40 |

24 |

56 |

|

Rd36 |

10.0 |

LHS05-36475 |

475 |

48 |

28 |

69 |

|

Rd42 |

12.5 |

LHS05-42550 |

550 |

54 |

34 |

80 |

|

Rd52 |

15.0 |

LHS05-52575 |

575 |

68 |

34 |

95 |

Safety factor 3:1

20 years of expertise producing threaded lifting systems for precast concrete, spanning from M thread to RD thread, with a variety of anchors, accessories (caps, plugs), lifting loops, swivel eyes, and other components. Everything is made in-house.

How it is used?

We work with you throughout the entire process, from initial design and planning to fabrication and installation. We understand that every project is unique, and we are dedicated to providing our clients with the personalized attention and support they need to ensure it is completed successfully. Contact us for details!

Product display:

What’s your project?

After 20 years of just focusing in this industry, we have developed quite a full range of products for precast factories and their steel workshops, from all the 9 major types of precast lifting anchors and connection anchors, concrete reinforcement.

+ What types of products do we manufacture?

We do produce the complete range of all types of

Precast lifting anchors,

-- Lifting anchors, lifting eye anchors, off-set lifting anchors, lifting clutches, recess former;

-- Two-hole anchors, erection anchors, spread anchors, sandwich panel anchors, ring clutches, etc;

Threaded lifting sockets,

-- Lifting socket, wavy tail anchor, straight tail anchor, crown foot anchor, flat plate socket, bolt anchor socket, lifting loop, swivel lifting eye, etc.

Connecting systems

-- Cast-in channel, sandwich panel anchor, anchor pins, wire loop box, fiberglass connector pin, etc.

Fixing & Supporting,

-- Fixing socket, bended fixing socket, fixing insert with cross pin, etc.

+ What are the benefits of using lifting and connecting systems for the precast and prestressed concrete products?

Precast and prestressed concrete products offer many benefits, including reduced construction time, increased safety, superior strength, and improve durability. Lifting system possibility of establishing a connection in a safe, simple manner. The system consists of a wide range of sockets and a selection of accessories to allow most types of lifting applications.

ISO9001 and Intertek, CE marked, and products have been certified by TUV,SGS.

ERP and Digital management manage to every production process, Fully equipped labs for both mechanical & chemical properties.

Package & Delivery