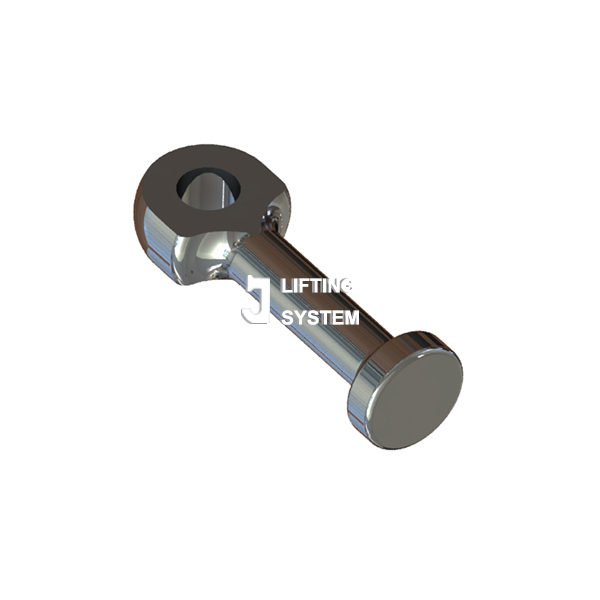

Lifting Eye Anchor

The Chontan Lifting Eye Anchor from China have enlarged heads designed to mate with lifting clutches. It was created for situations where it’s impossible to use conventional lifting anchor bases to transfer forces to the surrounding concrete. When used in combination with a reinforced anchor tail, lifting loads can be transferred deep into the concrete member.

Send Inquiry

Product Description

The Chontan Eye Anchor is used in combination with the rebar reinforcing pin. This combination allows tension loads to be distributed deeply into the concrete element and produce high safe working loads in thin wall sections.

It is primarily intended for usage in thin precast concrete structures with reinforcement, such as beams and girders. It is also appropriate for units made of lightweight precast concrete.

The Chontan Eye Anchor must be installed properly, centered and plumb to avoid drastic reduction of safe working load.

The lifting eye anchor was created for situations in which the regularlifting anchor base could not be used to transfer forces into the surrounding concrete. Lifting loads can be transferred deep into the concrete element when used in conjunction with a reinforcing anchorage tail.

It is primarily intended for usage in thin precast concrete structures with reinforcement, such as beams and girders. It is also appropriate for units made of lightweight precast concrete.

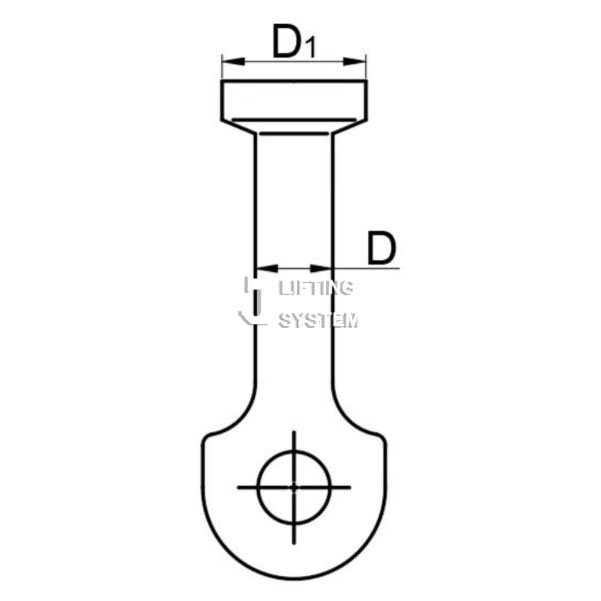

Size

SPECIFICATIONS

|

Rated Load |

Code |

Sizes (mm) |

||

|

Tons |

D |

D1 |

L |

|

|

1.3 |

L02-013 |

10 |

19 |

65 |

|

2.5 |

L02-025 |

14 |

26 |

90 |

|

5.0 |

L02-050 |

20 |

36 |

120 |

|

10.0 |

L02-100 |

28 |

46 |

180 |

|

20.0 |

L02-200 |

38 |

69 |

250 |

* Safety Factor is 3:1.

* Surface treatment: Surface Black (B) /Zinc Plate (Z.P) / Hot Dipping Galvanizing (H.D.G) are available.

* Stainless Steel 304 (A2)/316 (A4) are available according to the request.

* Other different Length are available according to the order.

Application Safety Guidelines:

- Please strictly follow the installation and use instructions of the Eye Anchor, and it is strictly forbidden to mix it with the system components of other manufacturers.

- When designing concrete precast parts, please refer to this description or the sample for calculation and design. If you need data other than this description, please contact us.

- Since the stress point will change the internal stress distribution of the prefab during hoisting, the stress calculation should be carried out according to the designed lifting state, and consider whether the prefab needs to be reinforced to avoid damage to the product.

How we produce?

We have 20 years of experience making lifting systems for precast concrete. Unlike other manufacturers, we invented our first semi-automatic forging process that produces these anchors faster and more efficiently. Everything is made in-house.

How it is used?

We work with you throughout the entire process, from initial design and planning to fabrication and installation. We understand that every project is unique, and we are dedicated to providing our clients with the personalized attention and support they need to ensure it is completed successfully. Contact us for details!

What’s your project?

After 20 years of just focusing in this industry, we have developed quite a full range of products for precast factories and their steel workshops, from all the 9 major types of precast lifting anchors and connection anchors, concrete reinforcement.

+ What types of products do we manufacture?

We do produce the complete range of all types of

Precast lifting anchors,

-- Lifting anchors, lifting eye anchors, off-set lifting anchors, lifting clutches, recess former;

-- Two-hole anchors, erection anchors, spread anchors, sandwich panel anchors, ring clutches, etc;

Threaded lifting sockets,

-- Lifting socket, wavy tail anchor, straight tail anchor, crown foot anchor, flat plate socket, bolt anchor socket, lifting loop, swivel lifting eye, etc.

Connecting systems

-- Cast-in channel, sandwich panel anchor, anchor pins, wire loop box, fiberglass connector pin, etc.

Fixing & Supporting,

-- Fixing socket, bended fixing socket, fixing insert with cross pin, etc.

+ What are the benefits of using lifting and connecting systems for the precast and prestressed concrete products?

Precast and prestressed concrete products offer many benefits, including reduced construction time, increased safety, superior strength, and improve durability. Lifting system possibility of establishing a connection in a safe, simple manner. The system consists of a wide range of sockets and a selection of accessories to allow most types of lifting applications.

ISO9001 and Intertek, CE marked, and products have been certified by TUV,SGS.

ERP and Digital management manage to every production process, Fully equipped labs for both mechanical & chemical properties.

Package & Delivery