Lifting Anchors

The Chontan lifting anchors from the Chinese manufacturer are made of round steel rods with forged feet and heads. It is suitable for the transportation of walls, pipes and floors. The anchorage height can be modified according to the intended use, making it the best choice for safe, application-specific load applications.

Send Inquiry

Product Description

A lifting anchor is a component used in concrete forming to provide a secure and safe way to lift and move concrete panels or other concrete structures during construction.

The lifting anchor is embedded into the concrete panel or structure during the casting process and serves as an attachment point for cranes or other lifting equipment to lift and move the panel or structure to its final position.

There are several types of lifting anchors used in concrete forming, including plate anchors, eye anchors, off-set lifting anchors, lifting clutches, and so on. Plate anchors are flat, rectangular-shaped anchors that are cast into the concrete panel or structure, and have a lifting hole in the center.

Eye anchors have a loop or eye-shaped attachment point and are used when a larger lifting point is required. Lifting clutches are designed to allow for rapid lifting and placement of precast concrete elements and typically feature a threaded end that allows for quick and easy installation.

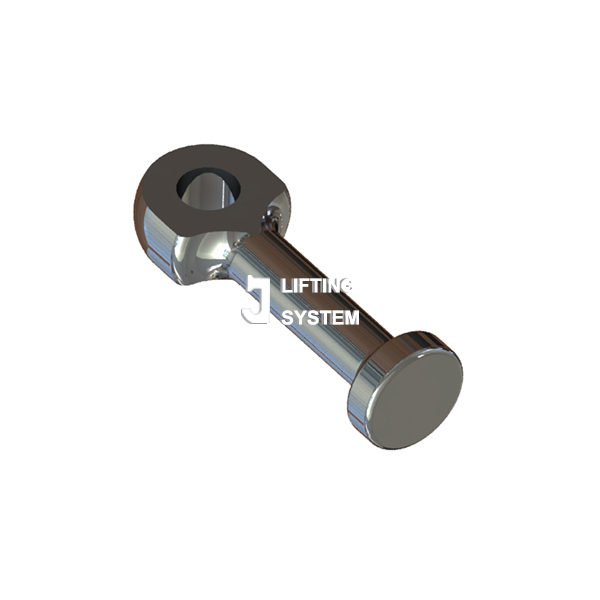

Lifting anchor/lifting stud anchor/spherical head anchor/capstan lifting anchor/dogbone anchor

Suitable for lifting and transporting all types of precast concrete elements under any condition

- Transport of wall and floor slabs, beams and columns

- Transport of sandwich panels

- Lifting and turning of concrete pipes

The lifting Anchor Lifting anchors are made of round steel rods with forged foot and head. It is intended for the transportation of walls, pipelines, and slabs and can be fixed on the component from the top or from the front. The anchor height can be modified according on the intended use, making it the best choice for a safe, application-specific load application.

The use of lifting anchors is essential in the construction industry as it allows for the safe and efficient movement of heavy concrete panels or structures, reducing the risk of accidents and damage to the concrete elements. It is important to follow proper installation procedures to ensure that the lifting anchor is securely embedded in the concrete and can withstand the weight of the concrete panel or structure during lifting and movement.

Material: High strength steel/Stainless steel AISI304/AISI316

Finish: Plain, Zinc-plated, Hot dip galv.

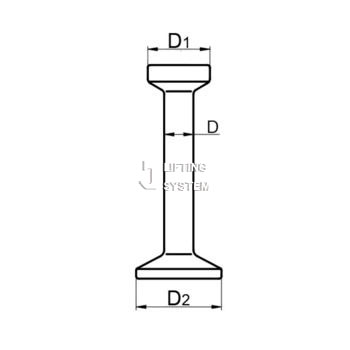

Size

SPECIFICATIONS

|

Rated Load |

Code |

Sizes (mm) |

AvailableLength (mm) |

||||||||||

|

Tons |

D |

D1 |

D2 |

L |

|||||||||

|

1.3 |

10 |

19 |

25 |

35 |

40 |

45 |

55 |

65 |

85 |

100 |

120 |

240 |

|

|

2.5 |

L01-025 |

14 |

26 |

35 |

55 |

65 |

85 |

120 |

140 |

170 |

210 |

240 |

280 |

|

4.0 |

L01-040 |

18 |

36 |

45 |

65 |

75 |

95 |

120 |

150 |

180 |

210 |

240 |

340 |

|

5.0 |

L01-050 |

20 |

36 |

50 |

75 |

95 |

120 |

170 |

180 |

210 |

240 |

340 |

480 |

|

7.5 |

L01-075 |

24 |

46 |

60 |

85 |

95 |

115 |

120 |

165 |

200 |

240 |

300 |

540 |

|

10.0 |

L01-100 |

28 |

46 |

70 |

85 |

100 |

115 |

135 |

170 |

200 |

250 |

340 |

680 |

|

15.0 |

L01-150 |

34 |

69 |

85 |

140 |

165 |

200 |

300 |

400 |

800 |

|

|

|

|

20.0 |

L01-200 |

38 |

69 |

98 |

200 |

240 |

340 |

500 |

700 |

1000 |

|

|

|

|

32.0 |

L01-320 |

50 |

88 |

135 |

250 |

500 |

700 |

1200 |

|

|

|

|

|

|

45.0 |

L01-450 |

50 |

88 |

135 |

250 |

500 |

700 |

1200 |

|

|

|

|

|

* Safety Factor is 3:1.

* Surface treatment: Surface Black (B) /Zinc Plate (Z.P) / Hot Dipping Galvanizing (H.D.G) are available.

* Stainless Steel 304 (A2)/316 (A4) are available according to the request.

* Other different Length are available according to the order.

How we produce?

We have 20 years of experience making lifting systems for precast concrete. Unlike other manufacturers, we invented our first semi-automatic forging process that produces these anchors faster and more efficiently. Everything is made in-house.

How it is used?

We work with you throughout the entire process, from initial design and planning to fabrication and installation. We understand that every project is unique, and we are dedicated to providing our clients with the personalized attention and support they need to ensure it is completed successfully. Contact us for details!

What’s your project?

After 20 years of just focusing in this industry, we have developed quite a full range of products for precast factories and their steel workshops, from all the 9 major types of precast lifting anchors and connection anchors, concrete reinforcement.

+ What types of products do we manufacture?

We do produce the complete range of all types of

Precast lifting anchors,

-- Lifting anchors, lifting eye anchors, off-set lifting anchors, lifting clutches, recess former;

-- Two-hole anchors, erection anchors, spread anchors, sandwich panel anchors, ring clutches, etc;

Threaded lifting sockets,

-- Lifting socket, wavy tail anchor, straight tail anchor, crown foot anchor, flat plate socket, bolt anchor socket, lifting loop, swivel lifting eye, etc.

Connecting systems

-- Cast-in channel, sandwich panel anchor, anchor pins, wire loop box, fiberglass connector pin, etc.

Fixing & Supporting,

-- Fixing socket, bended fixing socket, fixing insert with cross pin, etc.

+ What are the benefits of using lifting and connecting systems for the precast and prestressed concrete products?

Precast and prestressed concrete products offer many benefits, including reduced construction time, increased safety, superior strength, and improve durability. Lifting system possibility of establishing a connection in a safe, simple manner. The system consists of a wide range of sockets and a selection of accessories to allow most types of lifting applications.

ISO9001 and Intertek, CE marked, and products have been certified by TUV,SGS.

ERP and Digital management manage to every production process, Fully equipped labs for both mechanical & chemical properties.

Package & Delivery