Sandwich Panel Anchor

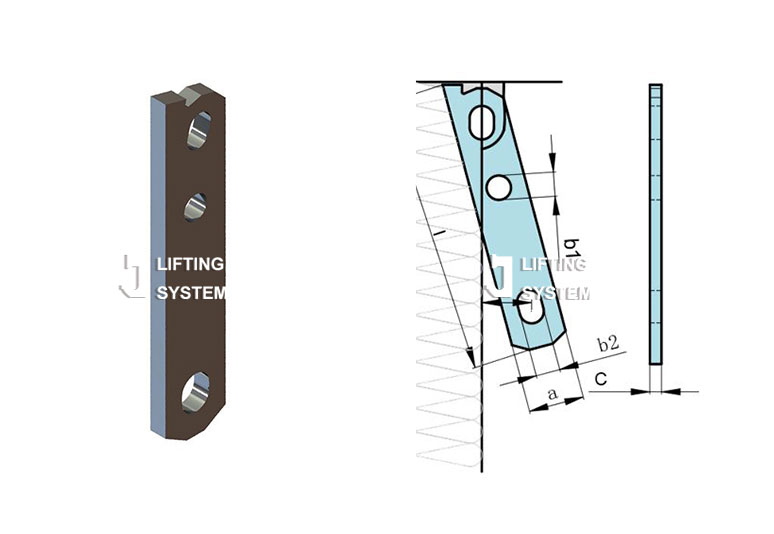

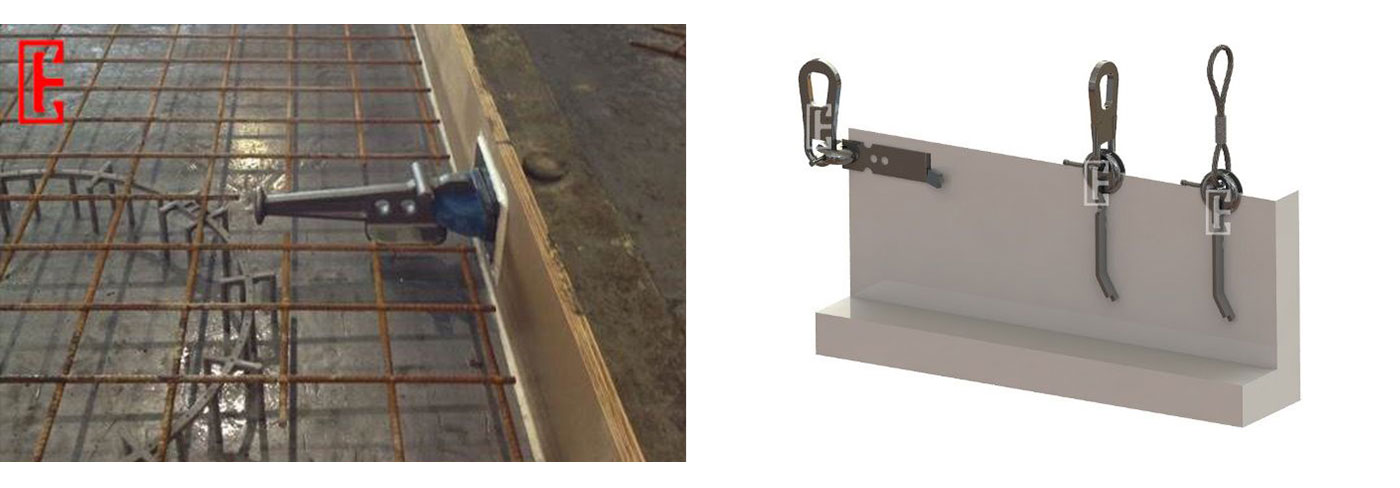

Chontan Sandwich Panel Anchor is intended for lifting insulated precast elements. Keep the anchor in the main structural element and the lifting point close to the panel's gravity line. The design allows the unit to be lifted in a straight position for usage in sandwich walls. Always use in conjunction with additional reinforcement.

Send Inquiry

Product Description

Sandwich Panel Anchor Discription:

The term "erection anchor" refers to several different types of anchors, such as the "erection anchor with shear plate," "erection anchor with shear plate and cross bar," "unilateral erection anchor," "edge lift erection anchor," "sandwich panel erection anchor," "x-foot erection anchor with shear plate," "universal erection anchor," "flat anchor," "plate anchor," "spread anchor," " Its primary use involves lifting thin-walled concrete components from a horizontal to a vertical position. The anchor head's unique form keeps the concrete from cracking. When tilting and turning activities are being performed, this type of anchor is often employed in conjunction with additional reinforcement.

We have a full line of alp erection anchors,contact us for the latest technical information

-

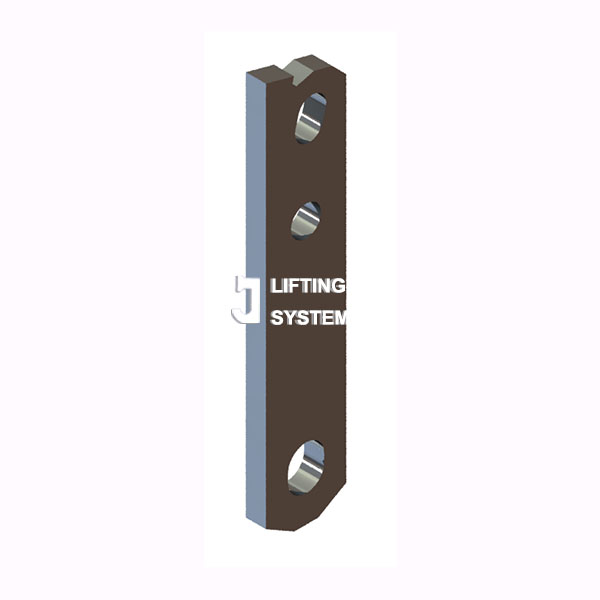

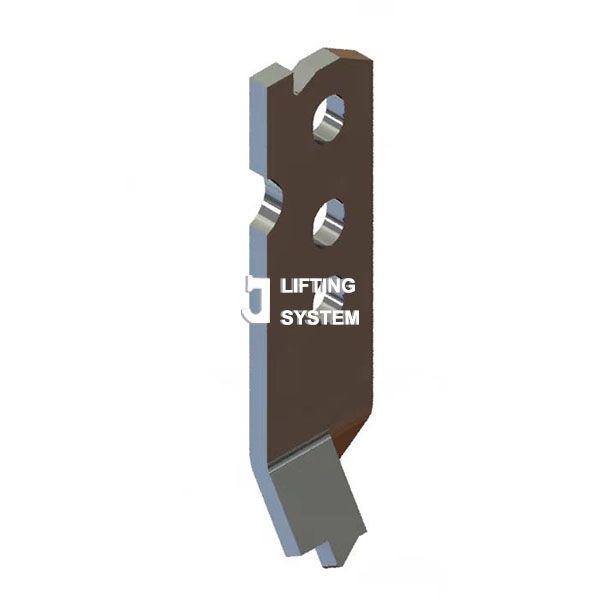

Two Hole Anchor

Two Hole Anchor

-

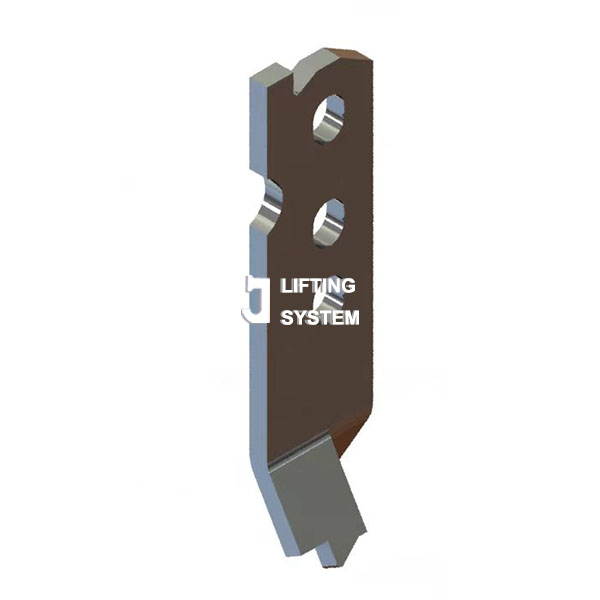

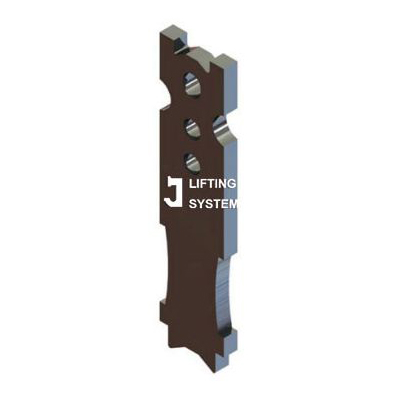

Erection Anchor

Erection Anchor

-

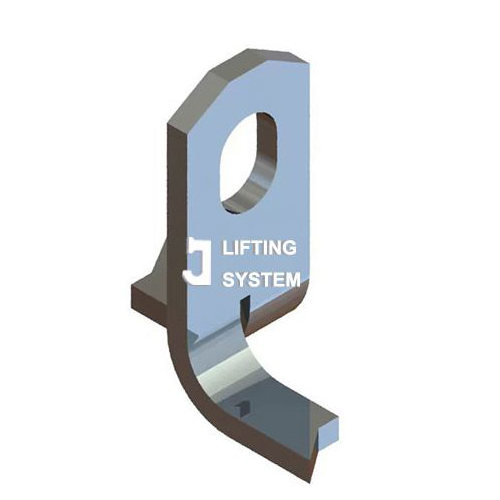

Spread Anchor

Spread Anchor

-

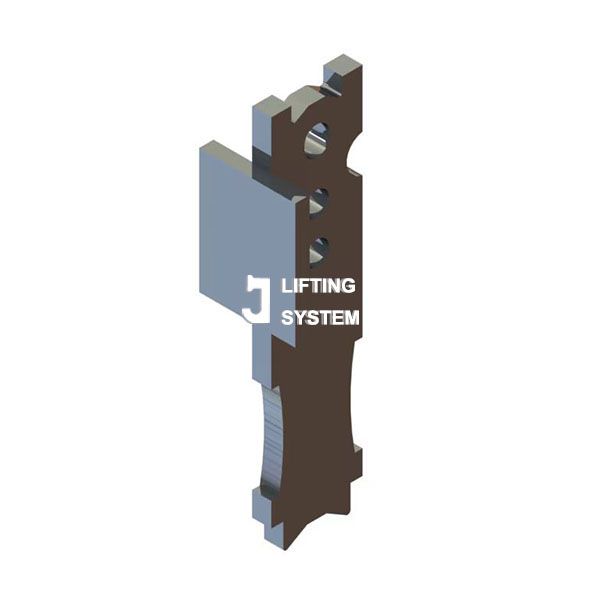

Unilateral Erection Anchor

Unilateral Erection Anchor

-

Spread Anchor

Spread Anchor

-

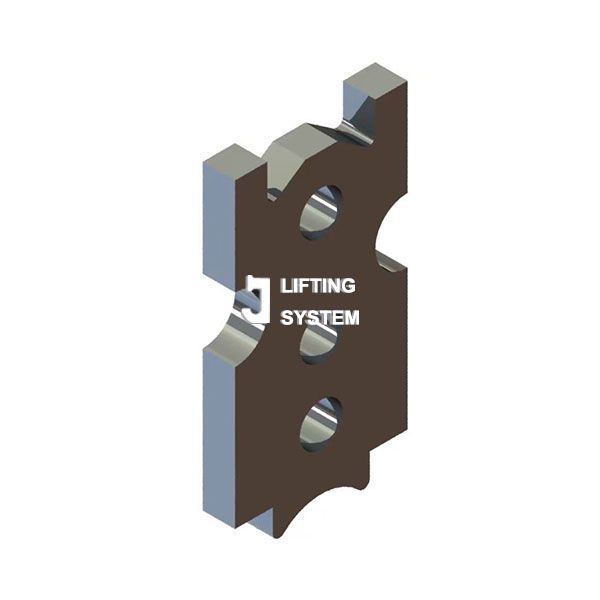

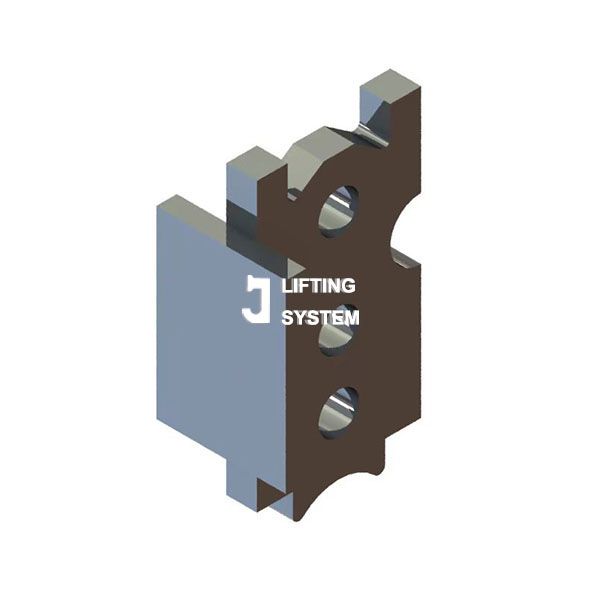

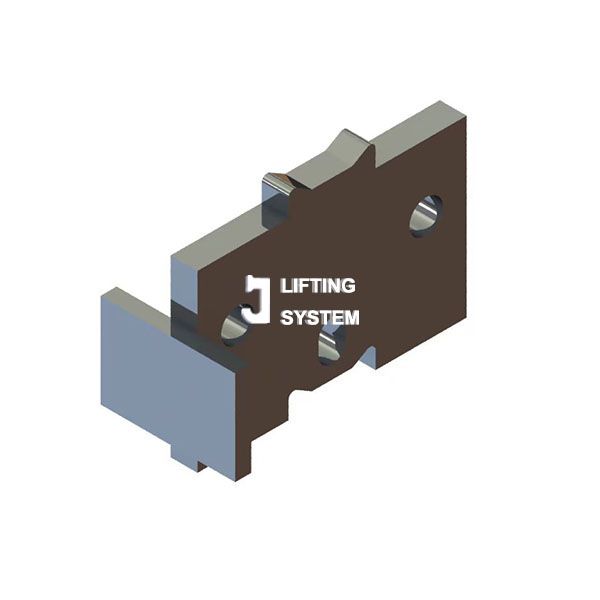

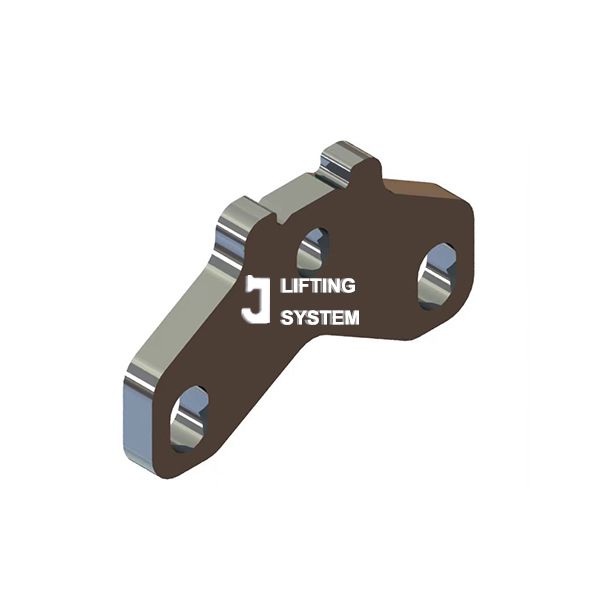

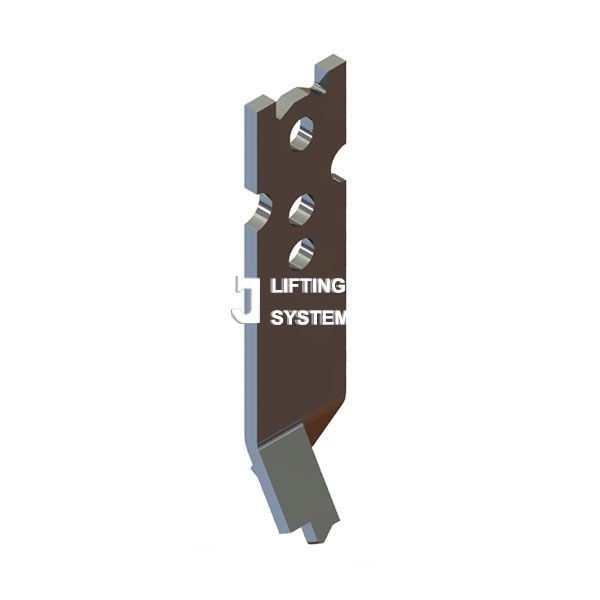

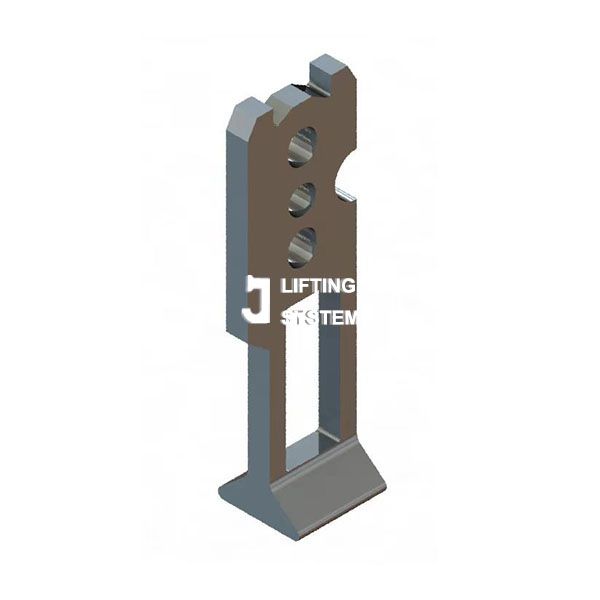

Sandwich panel Anchor

Sandwich panel Anchor

-

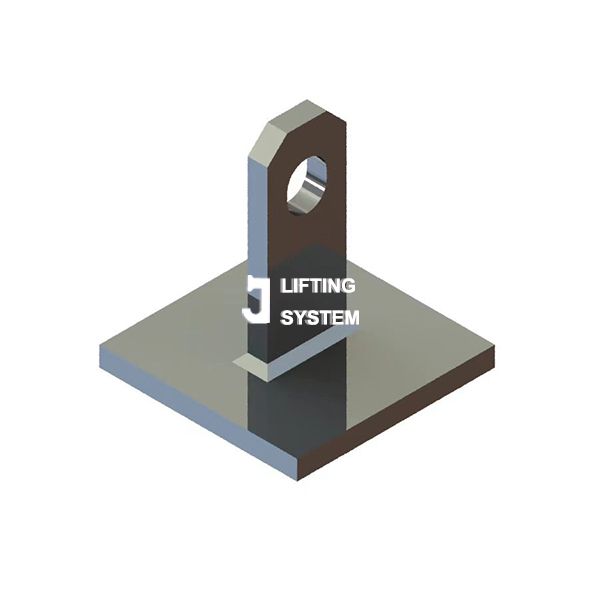

Plate Ring Anchor

Plate Ring Anchor

-

Tech Erection Anchor

Tech Erection Anchor

-

Tech Erection Anchor with

Shear plate

Tech Erection Anchor with

Shear plate

-

Insulated panel anchor

Insulated panel anchor

-

Insulated panel anchor with Shear plate

Insulated panel anchor with Shear plate

-

Forged Insulated panel anchor

Forged Insulated panel anchor

-

Erection head anchor

Erection head anchor

-

Erection head anchor with Shear plate

Erection head anchor with Shear plate

-

Ring Lift Uni-Anchor

Ring Lift Uni-Anchor

-

Forged erection anchor

Forged erection anchor

-

Forged erection anchor with shear plate

Forged erection anchor with shear plate

-

Drop Forged Foot Anchor

Drop Forged Foot Anchor

-

Forged Foot Erection Anchor

Forged Foot Erection Anchor

-

Split foot erection anchor

Split foot erection anchor

SPECIFICATIONS

|

Load Group |

Axial Load |

Code |

Dimensions (mm) |

||

|

Tons |

Tons |

L |

W |

T |

|

|

2.5 |

2.5 |

R06-025250 |

250 |

40 |

10 |

|

5.0 |

5.0 |

R06-050300 |

300 |

60 |

16 |

|

10.0 |

7.5 |

R06-075350 |

350 |

80 |

16 |

|

10.0 |

R06-100350 |

350 |

20 |

||

|

26.0 |

17.0 |

R06-170400 |

400 |

100 |

25 |

Sandwich Panel Anchor Package:

As the industry's top producer of precast concrete accessories, Chontan ensures that each of our products is checked before, during, and after production is complete. We offer customization for the packaging, which is typically made of a carton box, pallets, bags, and a plywood box.

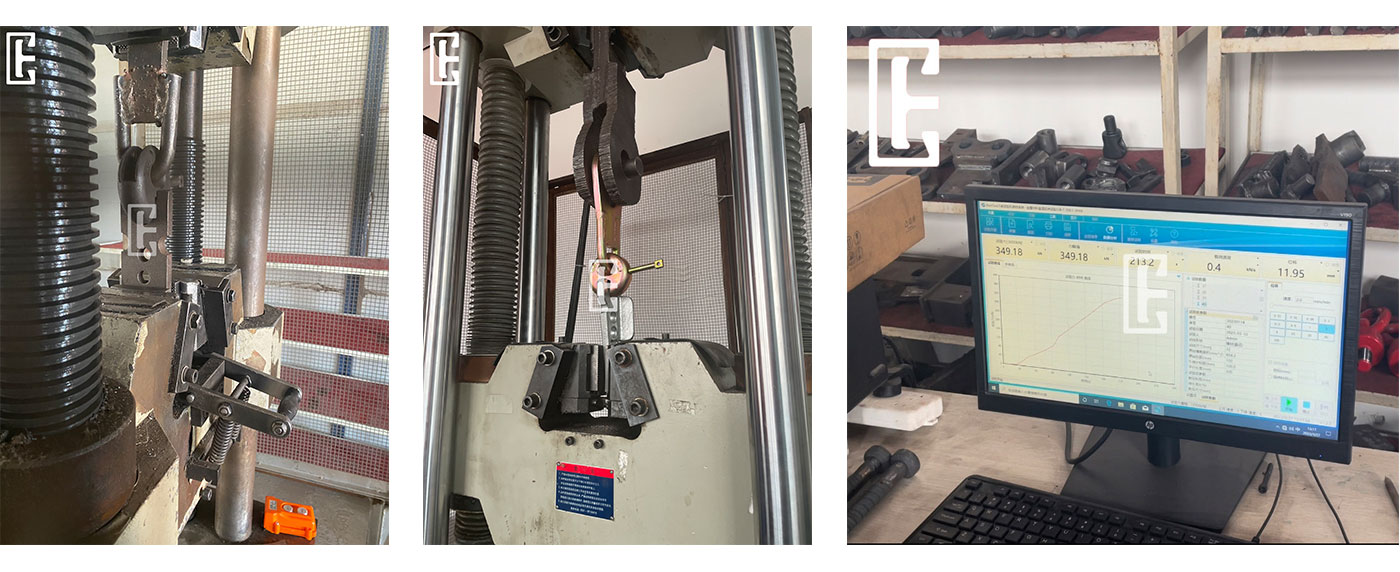

Chontan Advantage:

Design to eliminate spalling during lifting.

High toughness by special heat treatment

More compact structure by hot precision forging

A whole set of advanced mechanical processing facilities for forging

Application:

Fixed use for connecting structural components or non-structural components.

Test of Sandwich Panel Anchor

Certification of Sandwich Panel Anchor: